What is a consolidation warehouse? For starters, it’s what you need when traditional warehousing just doesn’t cut it anymore. With the changes in our economy, the growth and demand of the population, and expectations set by eCommerce. The shipping industry needs a new ally, and that ally is consolidation warehousing.

Through consolidation warehousing, advanced technologies like WMS and AVGs are used to sort, store, batch, and ship goods throughout North America. This form of warehousing consolidates small shipments quickly and organizes a complete truckload shipment based on destination with a swift approach to load times and delivery.

Using a transload services option like a consolidation warehouse is a clever play for any business. Learn more about this exciting new way of warehousing and distributing.

What is a Consolidation Warehouse?

A consolidation warehouse is a warehouse that is operated by a third-party logistics (3PL) company that is responsible for merging small loads into large-size shipments. Facilities use advanced technology to deal with small orders and combine them in a way to maximize distribution.

These facilities are directly responsible for pairing goods to fill truckloads bound for similar destinations. In a way, this strategy is equal parts staging goods for delivery to other similar destinations and filling truckloads to maximum capacity for shipment.

Consolidation warehouses are where cargo is processed, organized, and distributed. The complexity in the process stems from whether or not the goods are stored in boxes or loaded on pallets. In short, the whole point of this methodology is consolidation, as the term suggests.

Warehouses receive orders from a wide range of parties including:

- Suppliers

- Vendors

- Manufacturers

With the right system, a warehouse can effectively combine a customer's order and load it with others going to a similar destination.

In the end, a consolidation warehouse brings flexibility, efficiency, and organization to the world of logistics in a very modern way. With the rising popularity of eCommerce, consolidation warehouses are the go-to platform due to their experience in the logistical facilitation of goods.

Advantages of a Consolidation Warehouse

There are clear advantages of a consolidation warehouse in logistics. As mentioned, flexibility and efficiency are essential positives to a consolidation warehouse, but they are not the only advantages.

The list below outlines key advantages of what a consolidation warehouse brings to your shipments.

- Reduced inventory levels: Rotating goods at high speed while maintaining adequate supply.

- Increased efficiency: Sustaining a high frequency in shipments while operational efficiency prevents any bottlenecks.

- Fuel cost savings: Substantial savings in fuel cost with fewer trips resulting in a lower fuel emission footprint.

- Reduced claims: Reducing the number of people handling goods ultimately reduces the chance of loss and theft.

- Customer satisfaction: Increased speed, efficiency, cost savings, and a reduced chance of damage or theft result in improved customer satisfaction.

The advantages of consolidation stem from all of these factors, which bring positive results and clear benefits to keeping a supply chain moving. Maintaining a healthy and lag-free supply chain is essential for shippers and their customers.

Disadvantages of a Consolidation Warehouse

There are very few disadvantages to consolidation warehousing. These disadvantages, though, do generally occur when certain aspects of the process are missed, delayed, or poorly planned.

The following two topics outline any shortcomings that might happen when consolidating.

- Time Management: Time spent organizing loads and route planning is significantly increased. Increased preplanning without sufficient staff and resources can lead to negative results.

- Complex Communication: The amount of cross-talk between a shipper and 3PL or carrier is high. The risk of miscommunication can result in delays and errors in the fulfillment and transportation of freight.

A consolidation warehouse can lead to substantial positives and negatives, respectively. To effectively execute a consolidated warehouse strategy, advanced resources in staffing and available equipment are required to be effective in transloading freight.

What Does Consolidation Mean in Shipping?

Consolidation in shipping is a direct reference to bridging the gap between multiple small shipments and grouping them into larger ones. The principle idea is simply creating an entire load by compiling smaller ones.

Consolidated shipments refer to the load itself. In the world of shipping, transloading provides the means to a shipment, whether it is a truckload, rail, barge, etc. However, shipping consolidation results from a consolidated warehouse combining the goods for shipment.

As outlined above, consolidation serves a similar purpose within the realm of shipping. For example, the benefit of combining less-than-truckload (LTL) shipments into full truckloads brings cost efficiency to the table.

For smaller businesses that comprise most of North America's companies, consolidated shipping is a powerful option for shipping costs and order fulfillment. However, it does come with its challenges in preparation and execution.

Automation in a Consolidated Warehouse

When automation occurs in a warehouse, it improves speed, efficiency, and accuracy to save money and sustain growth. Is it really possible that all of these categories can be achieved with robotics?

Through the use of both physical and digital automation, the areas of speed, efficiency, and accuracy are all improved to unbelievable levels. At the same time, consolidated warehouses enjoy the extended benefits that come with automation.

Naturally, when a consolidated warehouse deploys automation, the need for human workers is severely reduced or eliminated entirely in certain areas. It is also essential to acknowledge the connection that exists between physical and digital automation.

Automation Integration by 2025

| Type of Automation | Percentage of Systems in Use |

| Conveyor Systems | 5% |

| Sortation Systems | 6% |

| Maintenance Repair Operations (MRO) | 24% |

| Automated Guided Vehicle (AGV) | 15% |

| Picking Systems | 13% |

| Warehouse Management Systems (WMS) | 9% |

| Vertical Lift Module | 8% |

What does the connection between physical and digital automation? This connection highlights how digital software on board the physically automated devices will communicate with other digital systems like warehouse management software (WMS).

With the innovation of warehouse robotics, every aspect of the warehouse space has been transformed. This method of leveraging technological advancement has proven to push logistics beyond what some thought possible.

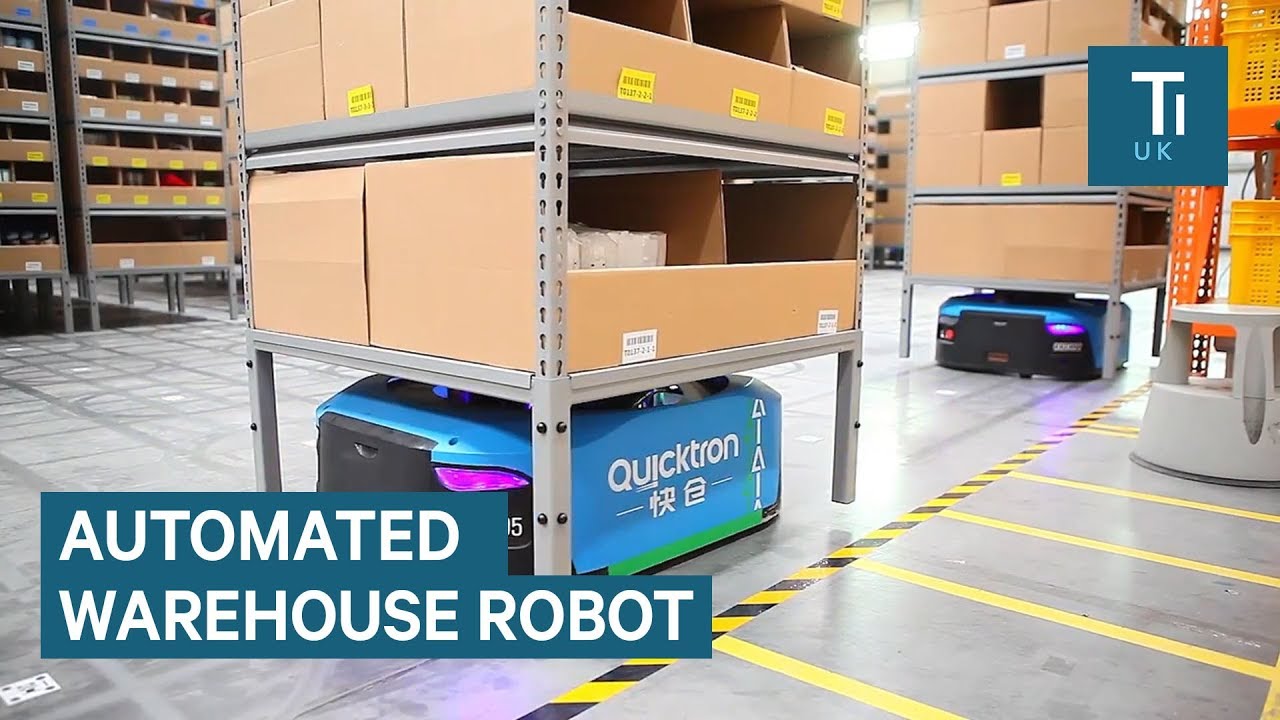

Warehouse AGV Technology

The technology that goes into automated guided vehicles (AGV) is some of the most cutting-edge technology ever created. The entire purpose of these advanced robots is to carry out the duties usually done by a human.

When done by an AGV, these duties are more efficient, accurate, cost-effective, and autonomous. These qualities lend themselves to a fully functioning 24-hour warehouse that operates at peak proficiency.

Key areas where AGV systems have a direct influence on warehouse functions:

- Sorting

- Storage

- Loading and unloading

- Inventory management

- Automated routing software

Each year, AGV technology rapidly expands while at the same time introducing new modern marvels which revolutionize the industry. These milestones bring a true benefit to the efficiency of a consolidated warehouse.

In the modern era of logistics, the use of AGVs is critically important for any consolidated warehouse. This is because there is increased demand for products to be shipped faster while reducing costs. AGVs open new doors for shippers, carriers, and 3PLs.

The Consolidation Process

The process of consolidating goods in a warehouse starts and stops with a Warehouse Management System (WMS). The purpose of a WMS is to manage the warehouse's inventory and set up a rotating storage solution while organizing the loading process.

There are multiple phases in the consolidation process at warehouse locations throughout the country.

The common parts of the consolidation process are outlined below. .

- Sorting: Goods enter a consolidated warehouse from multiple warehouses, distribution centers, and direct goods from manufacturers. The sorting process begins when all those goods are collected and sorted in a staging area.

- Storage: After goods have been sorted and staged, the WMS system preps an automated storage assignment. Personnel or AGVs can store the goods within the consolidated warehouse and prepare them for shipment.

- Batching: Separated and stored goods are brought together and bundled for staging before being loaded onboard an outbound transport. The batching process also includes gathering all related documents for shipping.

From start to finish, the process of consolidating goods in a warehouse is a very refined system that is proven to be not only highly functional but effective. As mentioned earlier, the consolidation process is not without difficulties and does require finesse and precision.

Most, if not all, consolidation warehouses use software automation, while others use a mixture of both software and physical automation. Using these technologies is critically important to ensure that goods flow without an issue throughout the consolidation process.

Learn about the expenses associated with this service in our article on consolidated freight costs.

Let Transload Services USA Consolidate Your Warehouse Today!

Are you in need of warehouse consolidation? Then look no further - let the experts at Transload Services USA help move your goods quickly. Our knowledgeable and friendly staff are eager to set you up with a premier transloading solution in North America.

Transparency and reliability are one of the major hallmarks of Transload Services USA. We offer every customer an unmatched and unique white glove experience. Our team is dedicated to your transload needs from the first to the last mile.

Additionally, we offer services like:

We have strategically located facilities nationwide with an incredible 24/7 support team. You can call us at (352) 282-4588 for more information or click to get in touch with one of our team members.