Transloading frac sand takes logistical resourcefulness and deep knowledge of the commodity to maintain product quality throughout the transportation phase and meet industry demand. This high purity mineral is extremely desirable in the energy industry for frac drilling.

Transloading frac sand is accomplished through storage options such as flat, silo, and dome pass-through solutions. Frac sand is then transloaded onto hopper rail cars or barges to transport mass tonnage in a single load. Once the shipment reaches a final rail terminal or port, multiple truckloads can transport loads.

Want to know more about what frac sand is? Why is it an essential commodity? How to ship it in large quantities with speed? The following article will answer those questions and many more.

Transloading Frac Sand: What is it and Why is it Needed?

Frac sand is a type of crystalline silica quartz material that is both a round grain and highly durable in nature. The primary purpose and use for frac sand rest in the oil and gas drilling industry. These industries acquire and produce this material due to its crush resistance.

Because of its purity, frac sand is more durable than its counterparts. Most alternative forms of sand are not stable. They are a mix of multiple rock types that don’t share the same durability as high purity quartz. The crush resistance of frac sand is much higher than other mineral options currently known or available.

The term “proppant” refers to the roundness of the grain, known as frac sand. This roundness is a critical feature that is so well suited for fracking. Why is it so essential to fracking? Its usefulness in shape prevents any created fractures from closing.

Using other minerals, such as bauxite, can make ceramics alternatives to frac sand and have a similar outcome. However, this alternative isn’t anywhere near as cost-effective and readily available as frac sand.

What is Fracking?

Fracking is the process of “hydraulic fracturing,” a drilling method used by oil companies to extract oil, natural gas, and geothermal energy. This drilling uses water and frac sand at high pressure while drilling horizontally.

Some important locations where fracking occurs:

- Eagle Ford shale geological area: This site rests in Northeast Texas and extends Southwesterly down to the Mexican border.

- Permian Basin: This site is another sizeable sedimentary basin in North America.

Both sites produce record-breaking amounts of natural gas and oil annually.They also have incredible transloading transference through rail lines with container cars and truckload staging areas.

The whole point of fracking is drilling into sedimentary rock beds. Frac sand is essential to this process of drilling. This rock is essentially pressurized mud that has small pores.

Various natural resources, such as natural gas and oil, are within these pores. This process for extracting these resources started in the late 1940s. However, it was refined in the 1990s due to the advancement of modern technology.

Frac Sand Demand and Production

The demand for frac sand in the United States and the rest of the world is at an all-time high.

The need for frac sand has increased to record-setting numbers annually in the domestic United States alone. As such, the demand for frac sand transloading services is also rising.

As shown in the table below, the demand for frac sand has increased annually. The projections beyond 2022 still show an upward trend for the production and fulfillment of frac sand for energy companies all across the United States.

Domestic Frac Sand Demand in Tons

| 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 |

| 42 million | 80 million | 113 million | 116 million | 120 million | 125 million | 133 million |

In 2012, the domestic demand was around 34 million tons of frac sand. Today it is well over 100 million tons and growing, as noted by industry experts. This incredible statistic shows tremendous growth in the production and acquisition of this material.

The exponential growth of the frac sand market is not restricted to the domestic United States. As far as the rest of the world is concerned, the frac sand industry has grown to nearly a seven billion dollar a year industry.

It is forecasted that the compound annual growth rate of the frac sand industry should reach an almost eight percent growth rate over the next five years. This growth would put the frac sand global market at around eleven billion dollars annually.

Frac Sand Storage Solutions

The storage and transportation of frac sand is a highly involved business. One of the single most significant threats to frac sand is moisture. For frac sand to maintain its integrity, the mineral must be kept free from condensation or moisture before actual use.

When you are looking for frac sand transloading services, you should consider the methods they use to limit exposure.

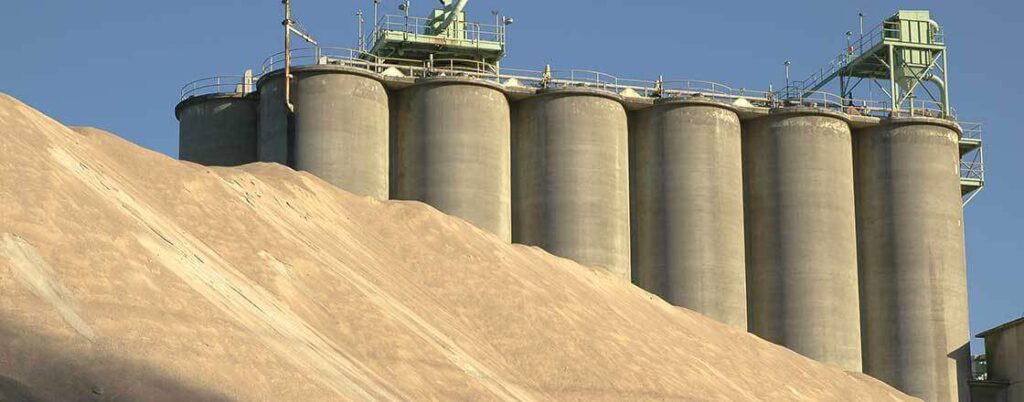

Frac sand is typically stored in flat storage, silos, and dome structures for sizeable dry bulk storage. A dome storage setup's key advantage is that domes generally have extensive waterproofing and insulation. This protection helps keep frac sand free from any damaging elements before shipment.

Frac sand storage solutions:

- Flat Storage: A flat storage solution is often large in scale with the look of a standard warehouse. With a traditional conveyance delivery system, this solution can load frac sand onto truckloads.

- Silo Storage: A vertical storage solution that offers better protection against frac sand elements than a flat storage facility. The only downside is that the storage capacity is typically far less than most flat storage solutions.

- Dome Storage: A dome storage is the best of both worlds in terms of storage.

In the video above, you see the process of frac sand being loaded onto a truckload platform using a "pass-through dome-silo" storage solution.

This storage solution is pretty incredible. It bridges the gap between protective storage and fast delivery for truckload operations while maintaining a sizeable overall storage capacity.

The Advantage of Transloading Frac Sand

The energy industry in the United States relies on fracking to keep the country free from global oil dependency. The demand for quality frac sand is at an all-time high domestically, and the United States produces some of the highest purity frac sand in the world.

With such a demand for mass quantities of frac sand, it is essential for frac sand shipments to be significant in scale and fast moving. This scenario is where frac sand transloading locations and services come into play.

- The Advantages of Transloading: These options free shipments from the restriction of single-mode transportation. Another point to note is that transload services can adapt to terrain constraints without jeopardizing speed and efficiency.

- Transload Services: This service flexes its muscle, as mentioned before, in the ability to move goods through different transportation methods as necessary. However, the sheer quantity of goods carried in a single instance sets this service apart.

- Trains and Barges: The tonnage that can be shipped through these methods is mind-blowing compared to traditional over-tucking. A single rail line transport can carry the tonnage capacity of around 300 over the road trucks. At the same time, barges can have an even greater capacity.

- The Benefits of Transloading: The benefits of this large capacity moving service are far more significant than traditional truckloads. The caveat to all of this rests in whether or not you have direct access to a rail terminal or barge port.

If you don't have a direct rail line or barge port access, truckload can offload your frac sand from barges or hopper rail cars through conveyor systems directly into your storage solutions, saving you real time and money.

Move Frac Sand Fast with Transload Services USA

Do you have a need to transload frac sand in bulk, fast, or both? Then let the experts at Transload Services USA help move your commodity quickly. Our friendly and knowledgeable staff can get you set up with the fastest and most cost-effective solutions available.

One of the hallmarks of Transload Services USA is our transparency and reliability while giving every customer a unique, unmatched white glove experience.

Our team is dedicated to seeing your transload requirements met every time, from the first to the last mile. With a wide-ranging portfolio of transloading options available to our customers, no task is too big, and no challenge will go unbeaten.

Our full suite of services includes:

We have strategically located transload facilities nationwide with 24/7 support. You can call us at (352) 282-4588 or click here to get in touch with one of our team members.