The climate of retail and eCommerce has shifted in recent years, and supply chains face daily disruption. So what is the answer to this problem? The answer is the fastest and most reliable distribution solution and the latest advanced technologies.

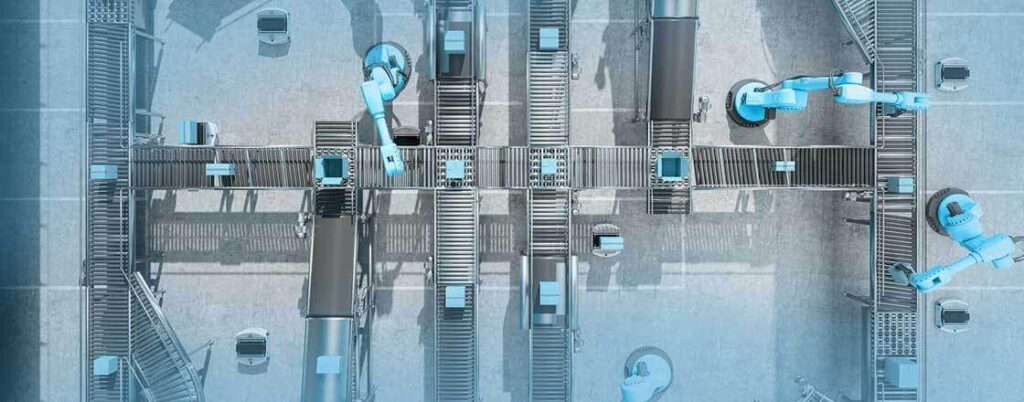

Cross dock automation is an improved form of traditional cross docking that deploys the latest in robotics and digital technology. With the use of automatic guided vehicles and autonomous mobile robots, among other technologies, the process of sorting, storing, loading, and unloading goods is faster and uses less power.

What is cross dock automation, and what does it mean for the average shipper? Find out the answer to that question and more in the article below.

What is Cross Dock Automation?

When asking the question, "what is automation?" A simple reply would be, "it's the supplementation of a robotic/software-driven application in place of a human one." What does this mean in plain English?

The best way to answer this statement is simple. Using robots to help us work better. But why is cross dock automation essential, you may ask?

The importance rests in a few key concepts:

- speed

- productivity

- accuracy

- efficiency

These key areas can influence the success or failure of any supply chain, fulfillment center, distribution center, or cross dock facility.

In any warehouse management system, organization and efficiency are paramount. As a shipper, you want to know that your goods are being processed, sorted, and shipped accurately every time.

Most, if not all, shippers would agree that cross docking as a shipping solution is among the best solutions for any supply chain. However, automation in cross docking takes things one step further. With automation, the technology of the 21st century is available to move goods faster and more efficiently than ever before.

Automation in Warehousing and Distribution

When it comes to automation in a warehouse or distribution setting, three main types currently take place. These systems deploy technology to improve high volume efficiency while giving shippers real-time transparency.

Warehouse automation is a new long-term solution offering reduced operation and shipping costs while improving customer experience. A recent case study has determined that as of 2019, automation has a near 61% adoption rate and is growing annually.

Software Automation

The sole purpose behind digital automation is to eliminate or minimize the possibility of human error. This is achieved by integrating systems with specialized software programs.

Such programs include:

- Inventory management software (IMS)

- Warehouse management systems (WMS)

- automatic identification and data capture (AIDC) software

- enterprise resource planning (ERP) systems.

The only drawbacks of implementing software automation are cost and security. The cost to acquire and maintain is pricey but worth it in the long run. As for security, since this is a connected system, cyber-attacks and the threat of being compromised are always a looming possibility.

That is why a team is required to maintain and protect any software system used in cross docking operations. These systems represent the backbone of what it takes to run and manage automated systems effectively.

Physical Automation

The use of physical robots or other software driven machinery is what physical automation is all about. These robots and other software controlled equipment are in direct contact with goods being processed at cross docking solutions for both inbound and outbound shipping.

Physical automation plays a crucial role in a modern inventory management system. Material handling is done effectively with precision and speed. This automation reduces the need for a human workforce while offering tremendous cost savings to logistics networks and shippers.

Orders are fulfilled with speed and accuracy while employing a minimized human workforce with a reduced possibility of human error. Automation itself has proven to be a system that can meet and exceed customer expectations in the transference of goods between the order process and delivery.

Cross Docking Automation and How it Works For You

Cross Docking solutions are really quite impressive both in form and function. With cross docking, inbound and outbound goods are rerouted to other trucks through short-term storage staging. The process effectively rewrites the shipping process in terms of supply chain distribution.

Cross docking automation neutralizes the need for both traditional warehousing and other forms of long-term storage. Traditional warehousing is costly and nowhere near as efficient as a cross docking solution. One of the most critical benefits of a cross dock facility is that palletized freight remains on its original pallets during the transference process.

The use of automation in an already fast distribution system, such as cross docking is genuinely incredible. When goods arrive at a cross dock facility, the movement of goods through storage options is reduced if not avoided altogether.

Fulfillment times are drastically reduced, along with increased cost savings that trickle down to the shipper. When a cross dock facility deploys both digital (software) and physical automation through IMS and WMS systems, the benefits are too significant to ignore.

Cross docking operations are all about getting goods distributed in the fastest and most accurate manner available. Speed and accuracy matter in the shipping world for distribution effectiveness and consumer demand. But why would a shipper care about whether a cross dock facility uses automated systems?

For starters, whenever a shipper is considering options for their supply chain, they need to concern themselves with the obvious. How fast can I get my orders fulfilled and shipped? Will there be any discrepancies or failures along the way? What cost-effectiveness can be presented?

A cross docking solution is the best answer to these questions, and the use of an automated cross docking operation is even better. The transformation of traditional cross docking to an automated one has seen many improvements that directly affect the shipper.

What Automated Equipment is Used?

There are many different forms of equipment used at cross docking facilities to improve the critical areas of shipping we have already discussed thus far, like speed, efficiency, and cost reduction.

When considering the process of storing and retrieving palletized or container goods, automated systems such as automated storage (AS) and retrieval systems (RS) come to mind. These two processes are critical for an automated cross dock solution.

Here are some examples of automated (AS+ RS) systems that benefit the shipper:

- Pick-to-Light and Put-to-Light: A mobile barcode device that scans using a digital display. This scanner reduces the amount of time spent searching for goods while minimizing human error.

- Pallet Conveyor: A conveyor system used for transferring palletized goods. It’s used for inbound and outbound operations, including short-term storage.

- Roller Conveyors: This system uses a roller system to transfer smaller boxed or containerized goods.

- Pallet Shuttles: These devices are semi-automatic and used for loading and unloading palletized goods and their storage. This equipment is run on electrical charging allowing for 24-hour operations.

- Automated Pallet Shuttles: This device provides automatic handling and is used for loading and unloading palletized goods and optimizing short-term storage..

- Stacker Cranes: This equipment is used for increasing vertical storage and sorting capacity while transferring goods quickly from an inbound or outbound load.

- Trilateral Stacker Cranes: This type of crane can extend the vertical storage option of a distribution facility or cross dock facility by nearly 50ft in height.

- Mini-Load Box Systems: This system is meant for loose box storage with quick access for both storage and acquisition for the loading and unloading of goods.

- Automatic Guided Vehicles: Often referred to as AGVs, they use onboard sensors that travel along magnetic strips. AGVs typically operate in wide open facilities that are less cramped for space.

- Autonomous Mobile Robots: Referred to as AMRs, they use active GPS to maneuver throughout a warehouse, distribution center, or cross dock facility. The accuracy of their onboard GPS allows for accurate navigation even in the busiest of environments.

All of this equipment is controlled with digital software for a semi to full automation with minimal human interaction. The purpose behind this equipment is for inventory accountability and the

mobilization and management of goods as they flow through cross docking solutions at higher than average speeds while minimizing costs.

How Does Automated Cross Docking Benefit The Shipper?

Automated cross docking has many benefits, mainly for the facility that uses this technology. However, the benefits are not just for the facility in question. Many of those benefits are felt by the shipper as well.

Cross docking on its own has multiple benefits for every shipper that uses it. With the main benefit being all about speed, an automated cross docking operation takes advantage of the shipper several steps further.

Here is some example benefits enjoyed by shippers who use an automated cross docking solution:

- Reduced shipping errors

- Reduced chance of damage or theft

- Reduced chance of stockouts

- Reduced shipping costs

- Increased real-time transparency

- Increased customer satisfaction

- Increased shipping accuracy and accountability

- Faster shipping times from start to finish

With the boom in eCommerce, we enjoy an economy that works 24 hours a day, 365 days a year. With this kind of operational demand, every edge is needed for fulfillment and shipping to operate at peak proficiency daily, especially when transloading your shipments.

eCommerce Growth 2018 - 2025

| 2018 | 2.98 Billion |

| 2019 | 3.35 Billion |

| 2020 | 4.25 Billion |

| 2021 | 4.94 Billion |

| 2022 | 5.54 Billion |

| 2023 | 6.21 Billion |

| 2024 | 6.77 Billion |

| 2025 | 7.41 Billion |

The above tables show the current trends of eCommerce by itself, not even considering brick and mortar retail from 2018 through 2021. The projected market trends show eCommerce exploding to nearly double digits in the billions, which clearly indicates the need for advanced technologies to meet the shipper's needs.

Through automation, especially in cross docking operations, shippers benefit from the absolute best in all categories regarding the proficiency and speed of their supply chain. Traditional warehousing and distribution simply cannot keep up with both consumer demand and the reality that is the modern era in commerce.

Should Automated Cross Docking Be A Priority?

For some time now, staffing has been an issue for warehouses, distribution centers, and cross docking facilities nationwide. The need to overcome this hurdle has strengthened the case for automation as a solution.

Supply chain disruptions are a constant issue that the United States and the rest of the world deal with daily. As noted above, supply and consumer demand are growing at a record pace. Shippers nowadays expect more progress in terms of fulfillment and distribution that meets or exceeds expectations every time.

That is why it is such a priority for shippers to modernize and use the best solutions available for their supply chain needs. Shippers want and demand various solutions, from complete visibility in real-time to fast to open communication.

This service extends to speedy on-time fulfillment and distribution to the safe and secure handling of their goods with minimal risk to damage and safety. However, above all else, cost-effectiveness is a principle topic regarding savings and services rendered.

Cross dock automation is the simple answer. As we have covered in this article, cross docking operations are among the fastest, safest, most transparent, and cost-effective solutions available today. When you automate that process, every benefit increases in effectiveness, and the shipper feels those benefits.

Transload Services USA Can Get Automation Working For You!

When looking to cross dock your supply chain, look no further. Transload Services USA is partnered with R+L Global Logistics to provide our customers with the best cross docking solutions and services.

Our cross docking solutions are strategically located across the United States. We offer reliable labor with the latest in automated technologies to keep your supply chain moving at record speeds.

We also provide the industry gold standard in transparency, communication, and support.

Our full suite of services includes:

Call us today at (352) 282-4588 or click here for more information, so we can get you moving at the speed of light!