Shippers looking to move large shipments of loose or oddly-shaped cargo often turn to container transloading to get the job done. This approach is specifically effective for shipments that move overseas or over long distances to multiple destinations.

Container transloading gives shippers the ability to better manage their inventory, transport additional cargo, reduce costs and increase supply chain efficiency. Transload containers are commonly used for overseas shipments but can be used for transloading between truck and rail as well.

Our guide below outlines the specifics of what container transloading is, when it should be used, and more.

What are Transload Containers?

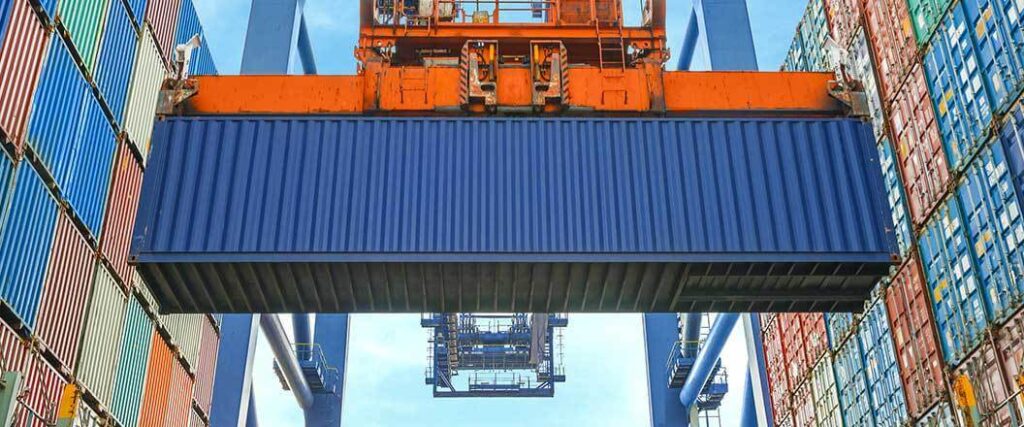

A transload container is simply a shipping container that is loaded with cargo and put onto a boat, truck, or rail car for transport. Once it reaches a transload facility, goods from the container are unloaded and either placed into a new container or straight onto another form of transportation for the next leg of the delivery.

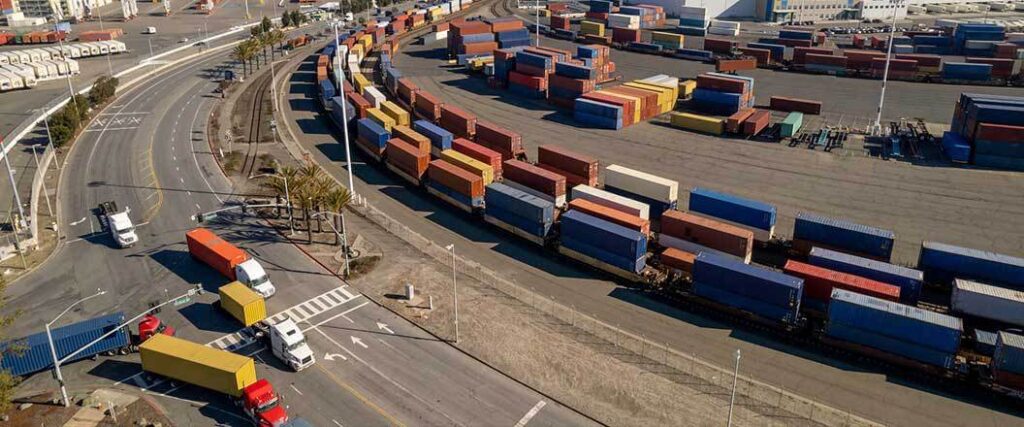

Transload containers are primarily associated with overseas transport and huge cargo ships, but container transloading can also occur between truck and rail. Transloading requires that a combination of at least two forms of transportation are used throughout the process. However, ships, trucks and rail cars are all used to haul shipping containers.

Shipping containers are typically made of corrugated steel with plywood flooring and double doors affixed to one side. While containers are universally measured in twenty-foot equivalent units (TEUs), they can generally be divided into domestic and maritime containers. Both of these types come in specific shapes and sizes.

When it comes to overseas shipping, fitting as many containers on board as possible is a priority.

As a result, maritime, or international containers, have some standard dimensions. These dimensions include:

- 20- or- 40-foot length

- 8-foot width

- 8-foot, 6-inch height

These units can typically be stacked up to 10 high.

Domestic containers, on the other hand, which are only used in North America, and primarily in the U.S., have slightly different standard dimensions:

- 48- or- 53-foot length

- 8-foot, 6-inch width

- 9-foot, 6-inch height (taller containers are referred to as high-cube containers)

Containers that are within the dimensions listed above are typically used for transport on road and rail.

Though both maritime and domestic containers are made of the same materials and constructed similarly, they differ in terms of their stackability. Domestic containers can only stack up to 3 units on top of each other, while maritime units go up to 10 high. However, oversized domestic containers can hold significantly more cargo.

Is Container Transloading Different than Intermodal?

Transloading is the process of transferring a shipment from one mode of transportation to another, typically with minimal handling involved. When transloading services are performed, goods are unloaded from their original containers and transferred into a new one before being loaded onto a new form of transportation for the next leg of the journey.

Intermodal is similar to transloading in that it involves the movement of goods using multiple forms of transportation. However, in intermodal shipping, the goods remain in the same container throughout the entire delivery, and it’s the container that’s transferred between modes of transportation, not the goods themselves.

Both transloading and intermodal are services used when one form of transportation won’t be enough to get the goods to their final destination. The two strategies are also used when it would be more efficient or cost-effective to move the goods using multiple forms of transportation.

Why Use Container Transloading?

The rise of international trade and eCommerce has led to increased use of both transloading services and containerized shipping. Shipping containers are among the best options available for moving large amounts of freight, especially overseas. Additionally, transloading doesn’t require a specific container to be used and is seen as both a way to lower costs and increase efficiency.

By using container transloading, shippers are able to load as much loose cargo or oddly-shaped items as can fit into a shipping container. At that point, the cargo is shipped overseas or across the country using multiple forms of transportation to get the job done.

There are many reasons why shippers would be inclined to use container transloading, from cost savings to inventory management. Some of the most common reasons are listed below.

Consolidation

There are many reasons to choose container transloading, but chief among them is the ability that it gives shippers to consolidate freight and save on transport costs.

Because maritime containers are limited to the 20-foot and 40-foot options, having the ability to consolidate the cargo into the larger 48- or- 53-foot domestic containers allows the shipper to load more cargo into fewer containers. The 48-foot containers have 29 percent more capacity than the standard 40-foot high-cube containers, while the 53-foot containers have 60 percent more capacity. That means that goods from three 40-foot containers are able to be consolidated into two 53-foot containers.

Generally speaking, the cost of moving shipping containers is based on the number of units being hauled, not their weight. So the fewer containers a shipper can consolidate their cargo into, the less money the shipper has to spend on transport costs.

Palletization

Typically, when goods are shipped from overseas, loose cargo is floor-loaded into shipping containers and then palletized once it reaches a transloading facility. Floor loading allows a shipper to fit as many goods as possible into one container, which is a priority for overseas shipments

Once a shipment reaches the facility, the goods will likely be sent to several different destinations or stored until needed. It makes more sense to unpack, sort and palletize the goods at that point than to do so prior to the cross-seas voyage. Once palletized, the goods are loaded into a new container and put onto an outgoing truck for final delivery.

Palletizing goods has some important benefits in the overall supply chain, including:

- Easier handling since pallets can be moved by pallet jack or forklift

- Faster loading and unloading

- More efficient storage

- Safer transport conditions

The benefits above make the palletization of products a no-brainer in most situations.

Supply Chain Management

Another advantage that the transloading process gives shippers is more control over their inventory management and more flexibility throughout the supply chain. This is especially helpful in reducing port congestion.

Typically, when a shipment is made without the use of a transloading service, it’s sent directly to the end-user. The destination is chosen well before the goods are shipped, and with no opportunity to redirect the shipment. The shipper is forced to complete the delivery as originally scheduled, regardless of how the market changes while the goods are in transit.

During container transloading, shippers are able to delay the decision and make adjustments to the final destination while the goods are still in transit. Once the goods reach the transloading facility, they will be unloaded, processed, and transferred to new containers. Based on how demand may have changed while the goods were on their way there, the shipper has the opportunity to redirect the goods or consolidate the cargo into shipments to a different store or warehouse.

Weight Compliance

While most shippers try to consolidate cargo into as few containers as possible, occasionally you may run into issues when a state or region has a specific weight limit. For example, many states in the U.S. allow specialized trucks to carry 55,000 pounds or more of cargo in a 40-foot container. However, in most of California, you’re only able to carry up to 47,000 pounds.

In some cases, you can get around this issue by using a specialized vehicle and by holding an overweight permit. However, if those options are unavailable, you may need to distribute the cargo across multiple containers at the transload facility to get each container under the weight limit before the delivery can proceed.

Demurrage and Detention

Demurrage and detention refer to the fees charged when a container is not returned where it belongs after a set amount of time. Demurrage occurs when a container has overstayed its allotted time at a terminal, while detention occurs when an empty container is past due for its return.

When a container is unloaded at a transloading facility, it’s able to be returned much more quickly, avoiding any additional fees. As opposed to intermodal shipping, the transload container never leaves the terminal itself. Instead, its goods are unloaded and transferred to a new container. Similarly, once the container arrives at the facility, it should be pre-cleared for unloading and transport so that it doesn’t overstay its allowed time at the terminal.

Find Your Transloading Solutions with Transload Services USA

Now that you know more about container transloading, let Transload Services USA help you get started. We use our vast network of locations and variety of services to get the job done right, no matter your supply chain needs.

Our team is equipped to handle any and all supply chain challenges you may face. We can handle all of your logistics needs, including:

Fill out a hassle-free quote today or call (352) 282-4588 and our team will get to work creating a strategy-driven and efficient approach for your supply chain needs.